Diamond Polishing Pads: Ultimate Guide to Features, Tech, Advantages & Uses

What Are Diamond Polishing Pads?

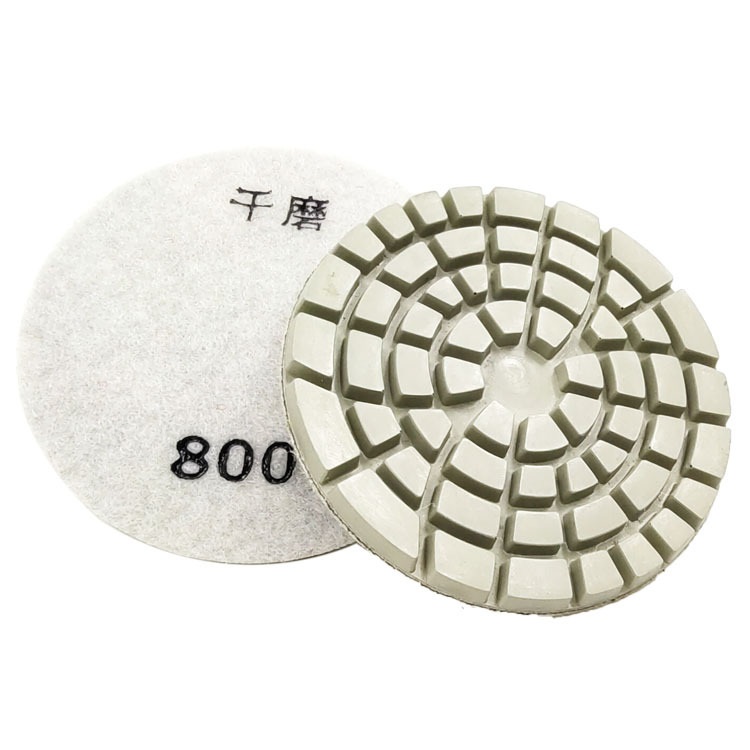

Diamond polishing pads are flexible or rigid abrasive tools embedded with diamond grit, designed to polish hard, non-metallic and metallic surfaces. The diamond particles—either synthetic (most common) or natural—are bonded to a backing material (like resin, foam, or fiber) in a precise pattern, allowing the pad to remove surface imperfections (scratches, dullness) and create a glossy, even finish.

Unlike grinding wheels (which focus on shaping), polishing pads prioritize surface refinement: they work by gradually abrading the material’s top layer, starting with coarse grit to smooth deep scratches and moving to fine grit for a high-gloss shine. This multi-step process ensures consistency and avoids damaging delicate surfaces.

Core Features of Diamond Polishing Pads

Diamond polishing pads stand out from other polishing tools due to four key features that define their performance:

1. Diamond Grit: The Foundation of Polishing Power

Diamond grit is what makes these pads effective—its Mohs hardness rating of 10 (the highest possible) lets it tackle materials up to 9 on the Mohs scale (e.g., granite, quartz, sapphire).

- Grit Sizes: Pads come in a range of grits, each designed for a specific stage of polishing:

- Coarse Grit (50–200): Removes deep scratches, unevenness, or rough surfaces (e.g., smoothing newly cut stone).

- Medium Grit (400–800): Refines the surface, eliminating coarse scratch marks and preparing it for shine.

- Fine Grit (1000–3000): Creates a subtle sheen, perfect for “matte” or “satin” finishes.

- Ultra-Fine Grit (5000–10,000): Delivers a mirror-like gloss (ideal for countertops, jewelry, or optical components).

- Grit Distribution: High-quality pads have evenly spaced diamond particles (often in a grid or spiral pattern) to ensure uniform polishing and prevent “hot spots” (areas where grit clusters and damages the surface).

2. Backing Material: Flexibility and Durability

The backing (the base of the pad) determines how well the pad conforms to surfaces and how long it lasts. Common backing materials include:

| Backing Type | Key Traits | Best For |

|---|---|---|

| Resin-Fiber | Rigid yet lightweight, excellent for flat surfaces (e.g., countertops) | Stone fabrication, concrete polishing |

| Foam | Flexible, conforms to curved or uneven surfaces (e.g., sink edges) | Bathroom fixtures, decorative stone, automotive parts |

| Velcro-Backed | Easy to attach/remove from polishers, reusable with multiple grits | DIY projects, small-scale polishing (e.g., tile touch-ups) |

| Rubber-Backed | Water-resistant, durable for wet polishing | Outdoor projects (e.g., patio slabs), glass polishing |

3. Bond Type: Holds Grit in Place

The bond (the adhesive that secures diamond grit to the backing) impacts the pad’s lifespan, polishing speed, and compatibility with materials. Three main bond types are used:

- Resin Bond: The most common—offers fast polishing, low heat generation, and works well with stone, ceramic, and glass. Ideal for wet or dry use.

- Metal Bond: Durable, slow-wearing, and designed for extremely hard materials (e.g., quartzite, concrete with aggregate). Best for wet polishing (reduces clogging).

- Vitrified Bond: Heat-resistant and rigid, perfect for high-speed polishing of metals (e.g., aluminum, stainless steel) or industrial ceramics. Less common for consumer use.

4. Wet vs. Dry Polishing Design

Many diamond pads are engineered for either wet or dry use (some work for both), with design tweaks to optimize performance:

- Wet Polishing Pads: Have drainage holes to channel water, which cools the pad, reduces dust, and flushes away debris (critical for stone or concrete).

- Dry Polishing Pads: Feature a porous backing to trap dust and prevent overheating. Ideal for indoor projects where water is impractical (e.g., polishing tile floors in a finished room).

Technical Specifications to Know

When choosing a diamond polishing pad, these technical details ensure you match the pad to your project:

- Pad Size: Ranges from 3 inches (small, handheld polishers) to 7 inches (industrial floor polishers). Smaller pads are for precision work (e.g., jewelry), while larger pads cover more area (e.g., kitchen countertops).

- Polishing Speed: Measured in RPM (rotations per minute). Most pads work best at 1000–3000 RPM:

- Coarse grits: Lower RPM (1000–1500) to avoid surface damage.

- Fine grits: Higher RPM (2000–3000) for a smooth shine.

- Density of Diamond Grit: Expressed as “carats per pad” (higher = more grit). For hard materials (granite), choose 5–10 carats; for softer materials (marble), 3–5 carats suffice.

- Thickness: Typically 3–5 mm. Thicker pads (5 mm) last longer, while thinner pads (3 mm) are more flexible for curved surfaces.

Key Advantages of Diamond Polishing Pads

Compared to traditional polishing tools (e.g., sandpaper, felt pads), diamond polishing pads offer five unmatched benefits:

1. Superior Finish Quality

Diamond’s hardness allows it to smooth even the smallest surface imperfections, resulting in a finish that’s impossible with other abrasives. For example, a 10,000-grit diamond pad can make granite countertops shine so brightly they reflect light—something sandpaper (max grit ~400) can never achieve.

2. Faster Polishing Time

Diamond grit cuts through material more efficiently than synthetic abrasives. Polishing a granite countertop with diamond pads takes 50–70% less time than using sandpaper: coarse grits remove scratches quickly, and fine grits refine the surface without repeated passes.

3. Longer Lifespan

Diamond grit wears at a fraction of the rate of aluminum oxide or silicon carbide. A single diamond pad can polish 50–100 square feet of stone (depending on grit) before needing replacement—compared to just 5–10 square feet with sandpaper. This reduces tool costs and downtime.

4. Versatility Across Materials

Diamond polishing pads work on nearly any hard surface, eliminating the need for multiple tools:

- Natural stone (granite, marble, quartzite)

- Engineered stone (quartz, solid surface)

- Ceramics and porcelain (tiles, sinks)

- Glass (shower doors, tabletops)

- Metals (aluminum, stainless steel, titanium)

- Concrete (floors, countertops, statues)

5. Reduced Surface Damage

Unlike harsh abrasives that can scratch or chip delicate materials (e.g., marble), diamond pads remove material gradually and evenly. Their controlled grit distribution and heat-dissipating design prevent “swirl marks” or “etching”—common issues with cheaper polishing tools.

Real-World Applications of Diamond Polishing Pads

Diamond polishing pads are used in countless industries and DIY projects. Here are the most common use cases:

1. Stone Fabrication (Professional)

- Countertops: Resin-fiber backed pads (50–10,000 grit) polish granite, quartz, and marble countertops to a high gloss. Wet polishing is preferred to reduce dust and cool the stone.

- Monuments and Statues: Metal-bonded pads smooth rough stone (e.g., limestone, sandstone) and refine intricate details without damaging carved surfaces.

2. Construction and Flooring

- Concrete Floors: Large (7-inch) dry or wet pads polish concrete floors in commercial buildings (offices, retail stores) to a sleek, modern finish. Coarse grits remove stains, while fine grits create shine.

- Tile Installation: Velcro-backed pads (400–1000 grit) touch up tile edges or repair scratches on porcelain or ceramic floors—perfect for DIY homeowners.

3. Automotive and Aerospace

- Automotive Parts: Foam-backed pads polish aluminum wheels, stainless steel trim, or carbon fiber components to a mirror finish. Dry pads are used to avoid water damage to electrical parts.

- Aerospace Components: Vitrified-bond pads polish titanium or composite parts (e.g., aircraft wings) to ensure smooth airflow and reduce friction.

4. Glass and Optical Industries

- Glass Tabletops/Shower Doors: Wet resin-bonded pads (800–3000 grit) remove scratches from glass and create a clear, streak-free finish. Drainage holes prevent water spots.

- Optical Lenses: Ultra-fine (5000–10,000 grit) natural diamond pads polish camera lenses, eyeglasses, or telescope mirrors to precise optical clarity.

5. DIY and Hobby Projects

- Jewelry Making: Small (3-inch) fine-grit pads polish gemstones (sapphires, rubies) or metal settings (silver, gold) to enhance brilliance.

- Home Renovations: DIYers use dry pads to refinish old marble fireplaces, polish concrete countertops, or touch up tile backsplashes—no professional equipment needed.

How to Choose the Right Diamond Polishing Pad

Follow these steps to select the perfect pad for your project:

- Identify the Material: Hard materials (granite, quartz) need metal or resin bonds; soft materials (marble, glass) work with resin bonds.

- Determine the Finish: Matte = 400–800 grit; satin = 1000–2000 grit; mirror = 5000–10,000 grit.

- Choose Wet/Dry: Wet for outdoor/stone projects (reduces dust); dry for indoor/tile projects (no water mess).

- Match to Your Polisher: Ensure the pad size and RPM rating align with your tool (e.g., a 5-inch pad for a 2000-RPM handheld polisher).

Post time: Sep-07-2025