Glass Drill Bits: A Complete Guide to Types, How to Use, Advantages & Buying Tips

Common Types of Glass Drill Bits

Choosing the right type of glass drill bit depends on your material and project. Here are the four most popular options, along with their strengths and ideal uses:

1. Diamond-Coated Glass Drill Bits

The most versatile and widely used type, diamond-coated bits have a metal shaft (usually high-speed steel or carbon steel) coated in tiny diamond particles—one of the hardest materials on Earth. The diamond coating grinds away glass gradually, creating smooth, chip-free holes.

- Key Features: Available in straight shank (for standard drills) or hex shank (for impact drivers), with diameters ranging from 3mm (1/8”) to 20mm (3/4”). Many have a tapered tip to guide the bit and prevent slipping.

- Best For: All glass types (thin, thick, tempered), ceramic tiles, porcelain, and marble. Perfect for DIY projects like installing glass knobs or bathroom tile fixtures.

- Pro Tip: Look for “electroplated diamond coating” (more durable than painted coatings) for longer life.

2. Carbide-Tipped Glass Drill Bits

Carbide-tipped bits have a tungsten carbide tip brazed to a steel shaft. While not as hard as diamond, carbide is still tough enough to cut through glass and ceramic, making these bits a budget-friendly alternative.

- Key Features: Typically have a spiral flute design to expel dust and debris, reducing heat buildup. Diameters range from 4mm (5/32”) to 16mm (5/8”).

- Best For: Thin glass (e.g., wine glasses, picture frames) and non-tempered ceramic. Avoid using on thick or tempered glass—they may cause cracking.

- Pro Tip: Use these for small, occasional projects; they wear faster than diamond bits with heavy use.

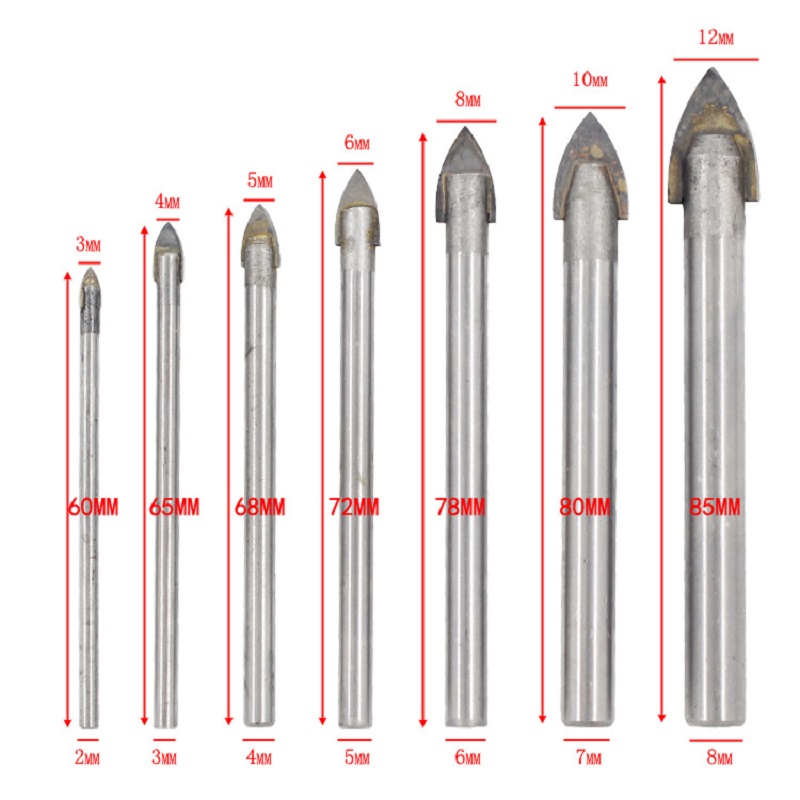

3. Spear Point Glass Drill Bits

Also known as “tile bits,” spear point bits have a sharp, pointed tip (shaped like a spear) with two cutting edges. They’re designed to start holes quickly and evenly, minimizing the risk of slipping.

- Key Features: Made from carbide or diamond-coated steel, with a short, sturdy shaft to reduce wobble. Most are 3mm–10mm in diameter.

- Best For: Ceramic tiles, glass mosaic pieces, and small holes (e.g., for grout lines or tiny fixtures).

- Pro Tip: The spear point is ideal for marking the hole’s center—no need for a separate punch tool.

4. Hollow Core Glass Drill Bits

Hollow core bits (or “hole saws for glass”) are cylindrical with a diamond-coated edge. They cut large holes by removing a “plug” of glass, rather than grinding away material.

- Key Features: Diameters range from 20mm (3/4”) to 100mm (4”), making them perfect for big projects. They require a guide (like a suction cup) to stay centered.

- Best For: Large holes in glass tabletops, shower doors, or aquarium tanks. Also works for thick porcelain sinks.

- Pro Tip: Use a slow drill speed (500–1,000 RPM) to avoid overheating the glass.

Key Features to Look for in Glass Drill Bits

Not all glass drill bits are created equal. These features determine how well a bit performs and how long it lasts:

1. Coating Quality

For diamond bits, electroplated diamond coating is non-negotiable—it bonds diamonds directly to the shaft, ensuring they don’t flake off. Cheaper “painted” diamond coatings wear away after 1–2 uses. For carbide bits, look for a polished carbide tip to reduce friction.

2. Shank Design

- Straight Shank: Fits most standard drill chucks (3/8” or 1/2”). Ideal for corded and cordless drills.

- Hex Shank: Prevents slipping in impact drivers, making it easier to apply steady pressure. Great for tough materials like thick ceramic.

- Shorter Shaft: Reduces wobble, which is critical for glass (even minor movement can cause cracks). Aim for shafts 50mm–75mm long for most projects.

3. Tip Geometry

- Tapered Tip: Guides the bit into the glass without slipping, perfect for beginners.

- Flat Tip: Distributes pressure evenly, ideal for thick glass or marble.

- Spear Tip: Starts holes quickly, great for tiles where precision is key.

4. Cooling Features

Glass cracks when it overheats, so look for bits with:

- Spiral Flutes: Expel dust and allow water (a cooling agent) to reach the cutting edge.

- Hollow Core: Lets water flow through the center, keeping the bit and glass cool during large cuts.

How to Use Glass Drill Bits (Step-by-Step Guide)

Even the best glass drill bit won’t work if used incorrectly. Follow these steps to avoid cracks and get perfect holes:

1. Gather Your Tools

- Glass drill bit (matching your hole size and material).

- Corded or cordless drill (set to low speed—500–1,000 RPM).

- Water (in a spray bottle or small bowl) to cool the bit.

- Masking tape (to mark the hole and prevent slipping).

- Clamp or suction cup (to hold the glass in place).

- Safety glasses and gloves (to protect against glass shards).

2. Prepare the Glass

- Clean the glass surface to remove dirt or oil—debris can cause the bit to slip.

- Apply a piece of masking tape over the area where you want the hole. Mark the center of the hole on the tape (the tape reduces chipping and helps the bit stay on track).

- Secure the glass with a clamp (if it’s a flat piece, like a tile) or a suction cup (for curved glass, like a vase). Never hold the glass by hand—sudden movement can lead to injury.

3. Drill the Hole

- Fill a spray bottle with water and mist the tape and bit. Water is critical—it cools the bit and glass, preventing overheating.

- Set your drill to low speed (high speed generates too much heat). Hold the drill straight (perpendicular to the glass) to avoid wobble.

- Apply light, steady pressure—let the bit do the work. Don’t push hard! Excessive pressure is the #1 cause of cracked glass.

- Pause every 10–15 seconds to spray more water and clear dust from the hole.

- When the bit starts to break through the other side (you’ll feel less resistance), slow down even more. This prevents the glass from chipping on the back.

4. Finish the Hole

- Once the hole is complete, turn off the drill and gently remove the bit.

- Rinse the glass with water to remove dust. Peel off the masking tape.

- For a smooth edge, use a fine-grit sandpaper (400–600 grit) to lightly sand the hole’s edges (wet-sanding works best to avoid scratches).

Advantages of Using Specialized Glass Drill Bits

Why not use a standard metal drill bit on glass? Here’s why glass-specific bits are worth the investment:

1. Prevents Cracking & Chipping

Standard bits have sharp, aggressive teeth that bite into glass, causing stress and cracks. Glass drill bits use gentle abrasion (diamond or carbide) to grind away material slowly, reducing stress on the glass.

2. Creates Clean, Precise Holes

Diamond and carbide coatings ensure smooth, even holes with no ragged edges. This is critical for visible projects (e.g., glass shelves, shower doors) where aesthetics matter.

3. Works on Multiple Materials

Most glass drill bits (especially diamond-coated ones) cut through ceramic, porcelain, marble, and even stone. This means one bit can handle your bathroom tile and glass mirror projects—no need to buy separate tools.

4. Long-Lasting Performance

Diamond-coated bits can cut 50+ holes in glass before needing replacement, while standard bits may break after just one use. This saves money over time, especially for professionals or frequent DIYers.

How to Choose the Right Glass Drill Bit (Buying Guide)

Use these questions to narrow down your options:

-

What material am I cutting?

- Thin glass/ceramic: Carbide-tipped or spear point bit.

- Thick/tempered glass: Diamond-coated bit (electroplated).

- Large holes (20mm+): Hollow core diamond bit.

-

What hole size do I need?

- Small holes (3mm–10mm): Standard diamond or carbide bit.

- Medium holes (10mm–20mm): Diamond-coated bit with a tapered tip.

- Large holes (20mm+): Hollow core bit (use a guide for accuracy).

-

What drill do I have?

- Standard drill: Straight shank bit.

- Impact driver: Hex shank bit (prevents slipping).

-

How often will I use it?

- Occasional use: Budget carbide-tipped bit.

- Frequent use: High-quality electroplated diamond bit (brands like Bosch, DeWalt, or Dremel).

-

Do I need extra features?

- Beginners: Tapered tip + spiral flutes (easier to use, better cooling).

- Professionals: Hex shank + hollow core (for speed and large projects).

Post time: Sep-20-2025