Glass Grinding Discs: Ultimate Guide to Features, Tech Specs, Advantages & Usage Tips

What Are Glass Grinding Discs?

Glass grinding discs are abrasive tools designed specifically for working with glass (including float glass, stained glass, tempered glass, and borosilicate glass). Unlike metal or stone grinding discs— which use coarse, hard abrasives—glass discs feature softer, more controlled abrasives that gently remove material without damaging the glass’s structure.

Most glass grinding discs consist of two main parts:

- Abrasive Layer: The working surface, made from materials like silicon carbide, diamond, or alumina, bonded to a flexible or rigid backing.

- Backing Material: Provides support to the abrasive layer. Common backings include resin (flexible, for curved surfaces), fiber (rigid, for flat edges), or rubber (shock-absorbent, for delicate work).

These discs attach to power tools like angle grinders, bench grinders, or specialized glass grinders, making them versatile for both small-scale DIY projects (e.g., repairing a glass vase) and large-scale industrial tasks (e.g., fabricating window panes).

Key Features of Glass Grinding Discs

Glass grinding discs are defined by features that address glass’s fragility and smoothness. Here are the most critical characteristics to look for:

1. Specialized Abrasive Materials

The abrasive used in glass discs is carefully selected to balance cutting power and gentleness:

- Silicon Carbide (SiC): The most common abrasive for glass grinding. It’s sharp yet relatively soft, making it ideal for removing burrs, smoothing edges, or preparing glass for polishing. Silicon carbide discs work well with all glass types and are affordable for everyday use.

- Diamond: For heavy-duty or precision tasks (e.g., grinding thick tempered glass or creating intricate bevels). Diamond abrasives are harder than silicon carbide and retain their sharpness longer—though they come at a higher cost. They’re often used in industrial settings or for high-end glasswork (e.g., stained glass art).

- Alumina (Al₂O₃): A milder abrasive, suitable for final smoothing or removing light scratches. Alumina discs are less likely to leave deep marks, making them perfect for pre-polishing steps.

2. Grit Size for Controlled Material Removal

Grit size (a measure of abrasive particle size) determines how much material the disc removes and the smoothness of the finish. Glass grinding discs typically range from 40 grit (coarse) to 1000 grit (fine), with specific uses for each:

- 40–80 Grit (Coarse): For heavy material removal—e.g., trimming excess glass, shaping rough edges, or fixing large chips. Coarse grits work fast but leave visible scratches, so they’re usually followed by finer grits.

- 120–240 Grit (Medium): For smoothing the surface after coarse grinding. Medium grits reduce scratches from coarse discs and prepare the glass for fine grinding or polishing. They’re ideal for general edge shaping (e.g., for a glass tabletop).

- 320–1000 Grit (Fine): For final smoothing or pre-polishing. Fine grits leave a nearly scratch-free surface, making them essential for projects where appearance matters (e.g., stained glass panels, decorative glassware).

3. Flexible or Rigid Backings

The backing material dictates the disc’s ability to adapt to glass shapes:

- Flexible Backings (Resin/Rubber): Bend easily to fit curved surfaces (e.g., glass bowls, rounded window edges). They’re also shock-absorbent, reducing the risk of cracking when applying pressure. Flexible discs are popular for DIY crafts and irregular glass shapes.

- Rigid Backings (Fiber/Metal): Maintain their shape for flat surfaces (e.g., glass sheets, mirror edges). Rigid discs deliver consistent pressure across the surface, ensuring even grinding—critical for industrial tasks like fabricating glass doors or shelves.

4. Water-Resistant Designs (Wet Grinding)

Many glass grinding discs are water-resistant (or “wet-use only”) because water serves two key purposes:

- Cools the Disc & Glass: Grinding generates heat, which can cause glass to crack. Water dissipates heat, protecting both the disc and the glass.

- Reduces Dust: Glass dust is fine and can be harmful if inhaled. Water traps dust, keeping the workspace clean and safe.

Water-resistant discs often have sealed backings or rust-proof cores to prevent damage from moisture. For dry grinding (less common for glass), look for discs labeled “dry-use”—though these are typically limited to light tasks (e.g., removing small scratches) to avoid overheating.

Technical Information: What Impacts Glass Grinding Disc Performance?

To get the best results, it’s important to understand the technical specs that influence how a glass grinding disc works. Here’s a breakdown:

1. Abrasive Bond Type

The bond holds abrasive particles to the backing, and its strength affects the disc’s lifespan and cutting speed:

- Resin Bond: The most common bond for glass discs. It’s flexible, heat-resistant, and releases abrasive particles gradually (self-sharpening), ensuring consistent performance. Resin bonds work well with wet grinding and are suitable for most glass types.

- Vitrified Bond: A rigid, ceramic-based bond. Vitrified bonds are more durable than resin and retain abrasives longer—ideal for heavy-duty industrial grinding (e.g., grinding large glass panels). However, they’re less flexible and require precise pressure control to avoid cracking glass.

- Rubber Bond: A soft bond used for fine grinding or polishing. Rubber bonds cushion the abrasive particles, delivering a smooth finish without scratching. They’re often used with diamond abrasives for high-gloss results.

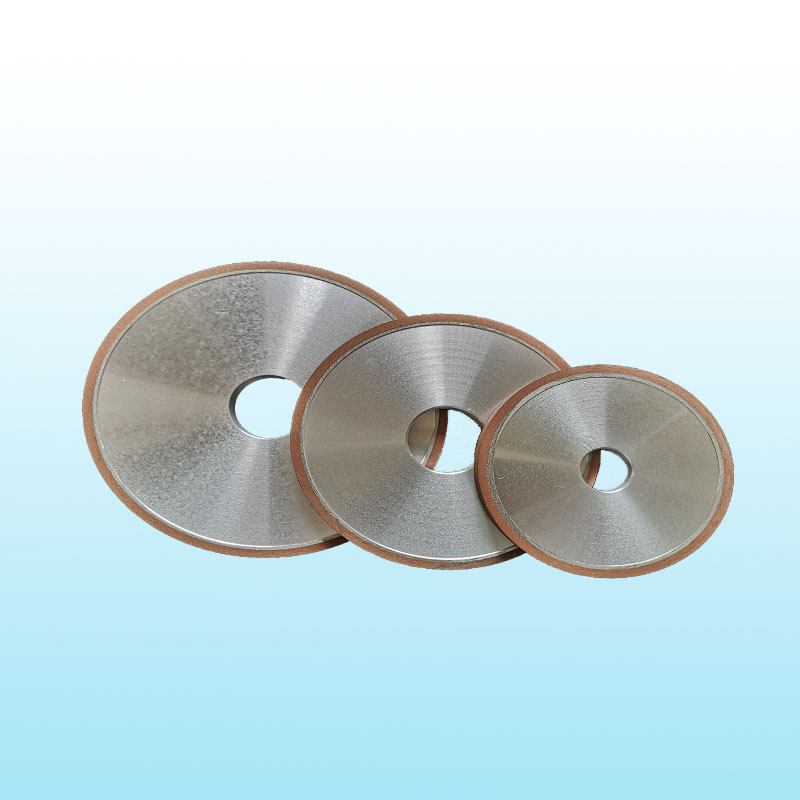

2. Disc Size & Compatibility

Glass grinding discs come in various sizes to fit different tools:

- Small Discs (3–4 inches): For handheld tools like angle grinders or die grinders. They’re ideal for small projects (e.g., repairing glass jewelry, smoothing small edges).

- Medium Discs (5–7 inches): For bench grinders or portable grinders. Suitable for medium-scale tasks (e.g., shaping glass table edges, grinding stained glass pieces).

- Large Discs (8–12 inches): For industrial machines like flat glass grinders. Used for large projects (e.g., grinding window panes, glass shower doors).

Always check the disc’s arbor hole size (the hole in the center) to ensure it fits your tool. Common arbor sizes for glass discs are 5/8 inch (for angle grinders) and 1/2 inch (for bench grinders).

3. Maximum RPM (Rotations Per Minute)

Each glass grinding disc has a maximum RPM rating, which indicates the fastest speed it can safely operate. Exceeding the maximum RPM can cause the disc to overheat, warp, or even break—risking injury and glass damage.

- Small discs (3–4 inches): Typically rated for 10,000–15,000 RPM (compatible with most angle grinders).

- Medium discs (5–7 inches): Rated for 6,000–10,000 RPM (suited for bench grinders).

- Large discs (8–12 inches): Rated for 3,000–6,000 RPM (for industrial grinders).

Always match the disc’s RPM to your tool’s speed setting—never use a disc with a lower maximum RPM than your tool’s minimum speed.

Advantages of Glass Grinding Discs Over Regular Grinding Discs

Using a disc designed specifically for glass offers significant benefits over generic metal or stone discs. Here’s why glass discs are worth the investment:

1. Prevents Glass Cracking & Scratching

Generic discs use hard abrasives (e.g., aluminum oxide for metal) that apply excessive pressure to glass, leading to cracks or deep scratches. Glass discs, by contrast, use softer abrasives and flexible backings that distribute pressure evenly, reducing the risk of damage. For example, a silicon carbide glass disc will smooth an edge without chipping, while a metal disc might shatter the glass entirely.

2. Delivers Precise, Consistent Results

Glass projects often require tight tolerances (e.g., a beveled edge for a mirror or a smooth edge for a glass shelf). Glass grinding discs’ controlled grit sizes and specialized abrasives ensure uniform material removal—so every part of the edge is smooth, and shapes are precise. Regular discs, with their inconsistent grit or hard abrasives, often leave uneven surfaces that require extra work to fix.

3. Longer Lifespan for Specific Tasks

While generic discs may wear out quickly when used on glass (due to glass’s abrasiveness), glass discs are engineered to withstand glass’s unique properties. For example, a diamond glass disc can grind hundreds of glass edges before needing replacement, whereas a metal disc might dull after just a few uses. This longevity saves money on replacements, especially for frequent users.

4. Safer for Wet Grinding

Most glass grinding discs are designed for wet use, which is critical for glasswork. Wet grinding reduces heat and dust, making the process safer for both the user (no inhalable dust) and the glass (no cracking from overheating). Regular discs often aren’t water-resistant—using them with water can cause rust, bond breakdown, or disc failure.

5. Versatile for Different Glass Types

Glass grinding discs work with all common glass varieties:

- Float Glass: Used for windows, tables, and mirrors—silicon carbide discs are ideal for edge smoothing.

- Tempered Glass: Harder than float glass—diamond discs handle grinding without shattering.

- Stained Glass: Delicate and thin—flexible resin-backed discs shape pieces without breaking.

- Borosilicate Glass: Heat-resistant (used in labware or cookware)—alumina discs smooth edges without damaging the glass’s heat resistance.

Generic discs, by contrast, may only work with one or two glass types, limiting their utility.

How to Choose the Right Glass Grinding Disc

Selecting the right disc depends on your project, glass type, and tool. Follow these steps to make the best choice:

1. Identify Your Task & Grit Size

- Heavy Shaping/Chip Repair: Choose 40–80 grit (coarse) silicon carbide or diamond discs.

- Edge Smoothing: Opt for 120–240 grit (medium) silicon carbide discs.

- Pre-Polishing/Fine Smoothing: Use 320–1000 grit (fine) alumina or diamond discs.

2. Match the Disc to Your Glass Type

- Float/Stained Glass: Silicon carbide discs (resin-backed for flexibility).

- Tempered/Borosilicate Glass: Diamond discs (vitrified or resin bond for durability).

- Curved Glass: Flexible rubber/resin-backed discs (3–5 inches for handheld tools).

- Flat Glass: Rigid fiber-backed discs (5–12 inches for bench/industrial grinders).

3. Check Tool Compatibility

- Handheld Angle Grinder: 3–4 inch discs with 5/8 inch arbor hole, 10,000–15,000 RPM.

- Bench Grinder: 5–7 inch discs with 1/2 inch arbor hole, 6,000–10,000 RPM.

- Industrial Flat Grinder: 8–12 inch discs with 1 inch arbor hole, 3,000–6,000 RPM.

4. Choose Wet or Dry Use

- Wet Use (Recommended): Select water-resistant discs (labeled “wet grinding” or “waterproof”).

- Dry Use (Only for Light Tasks): Look for discs labeled “dry-use”—avoid using wet discs dry, as this causes overheating.

Post time: Oct-13-2025