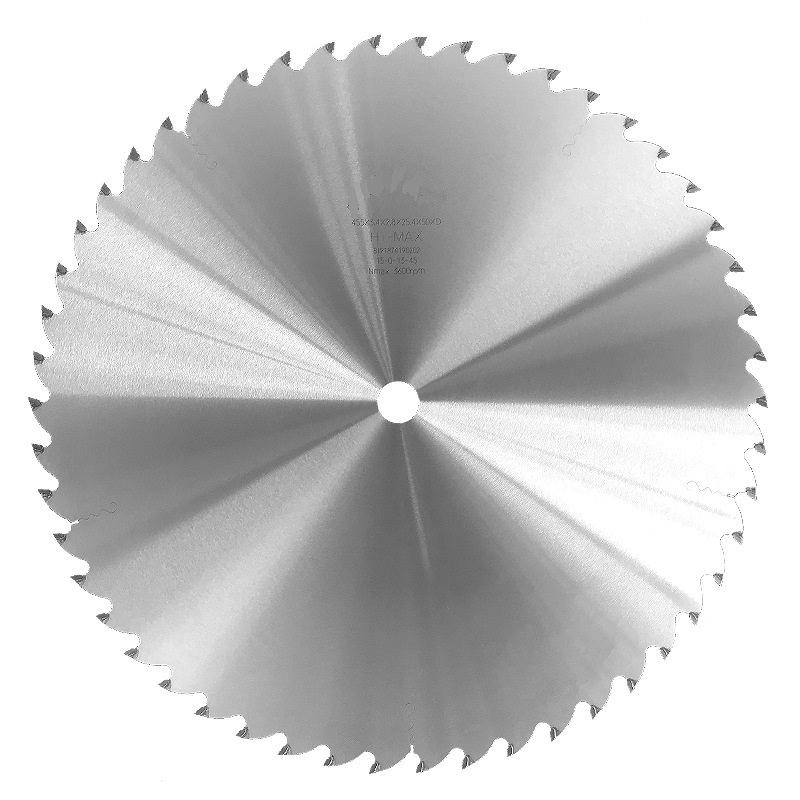

The Precision Edge: Unlocking the Power of TCT Saw Blades in Modern Cutting Applications

The Material Surgeon: How TCT Technology Revolutionizes Cutting

Tungsten Carbide Tipped (TCT) saw blades represent the pinnacle of cutting technology, combining surgical precision with industrial durability. Unlike conventional blades, TCT integrates micro-grain tungsten carbide teeth—the hardest material class short of diamonds—brazed or clamped onto high-tensile steel bodies. This hybrid design delivers unmatched performance across wood, metal, composites, and specialty materials, making it the undisputed champion in professional workshops and industrial settings worldwide .

Core Engineering: The Anatomy of Peak Performance

1. Advanced Material Science

- Tungsten Carbide Teeth: Engineered with YG8-grade carbide or cobalt-infused variants, these tips maintain sharpness 8-10x longer than HSS blades, even when cutting abrasive hardwoods (oak, teak) or stainless steel .

- Anti-Friction Coatings: PVD (Physical Vapor Deposition) coatings on blades like the NYX SS series reduce heat buildup by 40%, prevent material adhesion, and extend blade life 3x in stainless steel cutting .

- Shock-Absorbing Cores: High-fracture-toughness steel bodies (HRC 65) prevent warping during high-torque operations, critical for cold sawing metal where temperatures exceed 600°F .

2. Geometric Innovations

- Tooth Profiles:

- Conical Scoring Teeth: For laminate/veneer panels, conical teeth create splinter-free cuts by pre-scoring surfaces .

- Anti-Vibration Design: Spiral flutes (15–25° helix angles) in wood blades enable smoother chip evacuation, reducing noise by 15 dB and eliminating workpiece vibration .

- Oblique Clamping: Patented 45–90° screw angles in clamped blades enhance stability, minimizing tooth displacement during heavy-section steel cutting .

3. Precision Balancing

- Laser-calibrated tensioning ensures wobble ≤0.1mm, even at 660mm diameters. This prevents deflection when slicing thick-walled stainless steel tubes, maintaining cut tolerances within ±0.2mm .

Performance Advantages: Beyond Speed and Longevity

- Material Versatility

A single NYX series blade transitions seamlessly between:- Metals: Structural steel, aluminum (Bosun MAG350120L blades cut aluminum at 3,000 RPM), and stainless tubes .

- Wood Composites: Hardwoods, MDF, and phenolic laminates without tear-out .

- Economic Efficiency

- Extended Lifespan: 2–3x longer runtime than standard blades—20–24 hours on red sandalwood vs. 8 hours for carbon steel .

- Energy Savings: Optimized tooth geometry reduces power draw by 18% in cold-cutting applications .

- Surface Quality & Safety

- Burr-Free Edges: Cold-cutting technology keeps workpieces cool, preventing thermal distortion and eliminating secondary finishing .

- Dust Control: Spiral flute designs capture 95% of wood chips, reducing airborne particulates .

Application-Specific Solutions: Matching Blades to Tasks

Industrial Metalworking

- Thick-Section Steel: NYX DS PVD blades (660mm) with 180 teeth cut solid billets at 60–380 m/min. Wet cooling mandatory .

- Stainless Tubing: CHAOS series blades (400mm) use 4-flute TCT teeth to slice thin-walled tubes (5mm min) without collapse .

Woodworking & Composites

- Hardwood Bandsawing: TCT bandsaws cut oak at 25 m/s—twice the speed of carbon blades—with zero burning .

- CNC Machining: 25° spiral-angle router bits enable 2x faster feed rates in MDF carving vs. straight bits .

Specialty Cutting

- Aluminum Fabrication: 120-tooth blades (Bosun MAG350120L) prevent galling via alternating bevel teeth .

- Laminated Panels: Adjustable scoring blades create veneer-friendly kerfs as thin as 2.0mm .

Table: TCT Blade Selection Guide by Material

| Material Type | Blade Series | Key Specs | Optimal Feed Rate |

|---|---|---|---|

| Stainless Steel | NYX SS PVD 6 | 180 teeth, Ø225–660mm | 40–80 m/min |

| Hardwood | TCT Spiral 5 | 15–25° helix, 0.45x core ratio | 8–12 m/min |

| Aluminum | Bosun MAG 8 | 120 teeth, Ø350mm | 25–40 m/min |

| Concrete/Re-bar | SDS Plus 2 | 4-flute, YG8 carbide tips | 10–150 m/min |

Maximizing Blade Life: Maintenance Protocols

- Coolant Discipline: Water-soluble emulsions mandatory for metal cutting; dry cutting only approved for wood under 20mm thickness .

- Tooth Inspection: Check for carbide fractures every 50 operating hours—replace if chipping exceeds 0.3mm .

- Storage: Hang vertically in climate-controlled spaces; humidity >60% accelerates steel corrosion .

The Future Edge: Smart Blades and Industry 4.0

Next-gen TCT blades embed RFID chips to track tooth wear and cutting hours, syncing with CNC systems for auto-sharpening alerts. Meanwhile, nano-layered carbide coatings (under development) promise 5x lifespan in titanium cutting .

Conclusion: Precision as Standard

TCT saw blades transcend their role as mere cutting tools—they are engineered systems integrating metallurgy, geometry, and dynamics. Whether slicing stainless tubing with micron-level accuracy or carving hardwood with artistic finesse, they deliver flawless efficiency. For fabricators seeking zero-waste production or woodworkers demanding gallery-ready finishes, investing in application-specific TCT technology isn’t optional—it’s the bedrock of competitive craftsmanship.

Post time: Jul-20-2025