The Ultimate Guide to Diamond Core Bits: Revolutionizing Precision Drilling Technology

Types and Classifications of Diamond Core Bits

Types and Classifications of Diamond Core Bits

Diamond core bits come in various configurations, each designed to address specific drilling challenges and material types. Understanding these classifications is essential for selecting the appropriate bit for any given application.

Dry vs. Wet Diamond Core Bits

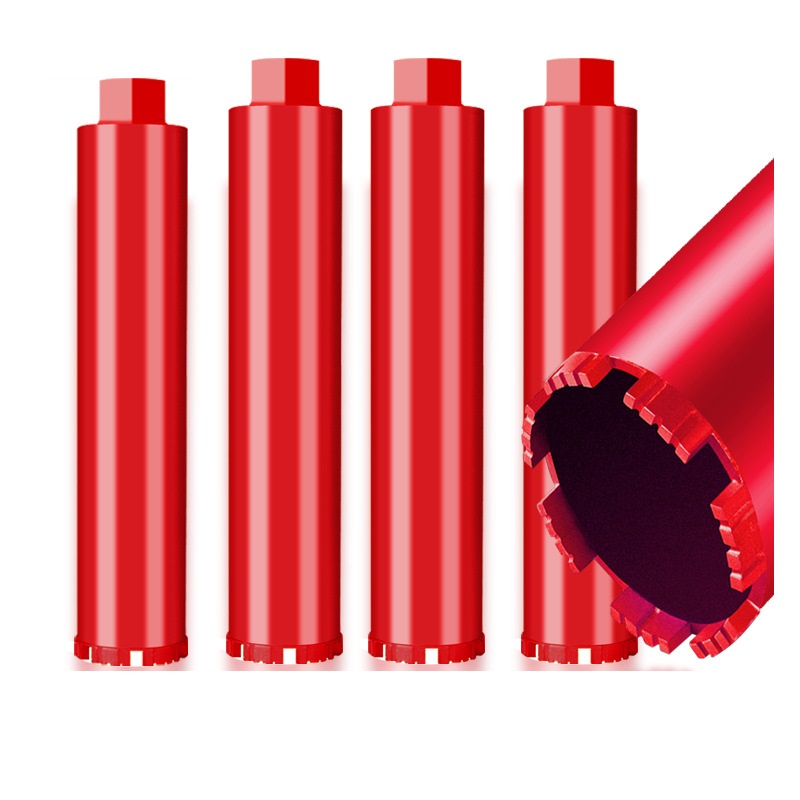

One of the primary distinctions in diamond core bits lies in their cooling mechanisms. Dry diamond core bits, such as the CorePlus CORDCDKIT7 set, are designed for operations where water cooling is impractical or undesirable 1. These bits typically feature a ribbed core body and V-groove segments that enable fast clearing of debris, allowing for continuous cutting action. The aerated core design enhances cooling and extends core life, making them ideal for overhead drilling situations or where water-sensitive materials are being worked on.

Wet diamond core bits, on the other hand, require water cooling during operation to prevent overheating and extend the life of the bit. These bits, such as the 25-102mm laser-welded wet diamond core bits, are specifically engineered for reinforced concrete drilling and offer superior cooling capabilities that allow for deeper and faster penetration in tough materials 8. The water serves both as a coolant and as a means to flush out drilling debris, maintaining cutting efficiency throughout the operation.

Impregnated vs. Surface-Set Bits

Another important classification distinguishes between impregnated and surface-set diamond core bits. Impregnated bits feature diamonds distributed throughout the matrix of the bit, such as the 61.5mm impregnated diamond core bit designed for granite hard rock drilling 6. As the matrix wears down during operation, fresh diamonds are continuously exposed, maintaining the bit’s cutting efficiency over an extended period.

Surface-set bits have diamonds exposed on the surface of the matrix, providing aggressive cutting action ideal for softer materials. These bits typically offer faster initial cutting speeds but may wear more quickly than impregnated designs in abrasive applications.

Specialized Design Varieties

Various specialized diamond core bit designs have emerged to address specific drilling challenges:

- PDC (Polycrystalline Diamond Compact) bits: These bits, featuring synthetic diamond cutters, are extensively used in oil and gas exploration as well as geological core sampling 3. They offer exceptional durability and cutting efficiency in both soft and medium-hard formations.

- Concave diamond element bits: Innovative designs like the StrataBlade bits leverage unique geometry cutters with distinctive concave features that decrease the effective cutter back-rake angle, enabling deeper cutting into abrasive and impact-prone rock .

- Tile-specific bits: Specialized diamond core bits like the Würth Diamond tile dry core bit M14 seat are engineered specifically for drilling through extremely hard ceramic materials without water cooling .

Technical Specifications and Design Features

Diamond core bits incorporate sophisticated engineering and precise manufacturing standards to ensure optimal performance across various applications. Understanding their technical specifications is crucial for proper selection and application.

Diamond Quality and Concentration

The performance of a diamond core bit largely depends on the quality and concentration of diamonds used in its construction. Industrial-grade diamonds are carefully selected based on size, shape, and strength characteristics to match specific drilling requirements. According to the DZ/T 0277-2015 standard for geological core drilling diamond bits, manufacturers must adhere to strict guidelines regarding diamond quality and distribution to ensure consistent performance .

Matrix Composition

The matrix, or the metal alloy that holds the diamonds in place, plays a critical role in determining a bit’s performance characteristics. The matrix must be engineered to wear at a controlled rate that continuously exposes fresh diamonds while maintaining structural integrity. Different matrix compositions are designed for specific formation types:

- Soft formation matrices: Softer bond materials that wear more quickly, ensuring constant diamond exposure in less abrasive formations.

- Hard formation matrices: Harder, more wear-resistant bonds that protect diamond retention in abrasive environments.

- Medium formation matrices: Balanced formulations that provide optimal performance in mixed formations.

Bit Design and Geometry

The physical design of diamond core bits significantly influences their performance:

Table: Diamond Core Bit Design Features and Their Functions

| Design Feature | Function | Application Examples |

|---|---|---|

| Water Channels | Allow coolant flow to cutting surface | All wet drilling applications |

| Segment Height | Determines bit life and wear resistance | Long drilling projects |

| Segment Pattern | Affects cutting speed and debris removal | Fast-paced construction work |

| Thread Type | Ensures compatibility with drilling equipment | Standardized drilling setups |

| Segment Width | Influences stability and cutting aggression | Precision drilling requirements |

The Husqvarna VARI-DRILL D25 DRY series demonstrates how sophisticated design features enhance performance, with specific segment configurations (3-4mm thickness, 9mm height) optimized for various concrete types .

Size Specifications

Diamond core bits are available in an extensive range of sizes to accommodate different drilling requirements. Standard sizes range from small diameter bits (as small as 1 inch/25mm for precision work) 4 to large diameter bits exceeding 200mm for major construction projects 7. The DZ/T 0277-2015 standard specifies precise dimensional tolerances for geological drilling bits, ensuring proper fit and function in professional applications .

Advantages and Benefits of Diamond Core Bits

The superiority of diamond core bits over conventional drilling technologies manifests in multiple aspects of drilling operations, providing tangible benefits to professionals across industries.

Exceptional Cutting Efficiency and Speed

Diamond core bits offer significantly faster penetration rates compared to conventional drill bits, particularly in hard and abrasive materials. The StrataBlade concave diamond element bits, for instance, have demonstrated up to 28% increase in rate of penetration (ROP) compared to conventional bits in field tests conducted in the Haynesville Basin 10. This enhanced efficiency translates directly into reduced drilling time and lower labor costs per project.

Precision and Quality of Cut

The unique cutting action of diamond core bits produces clean, precise holes with minimal chipping or material damage. This precision is particularly valuable in applications where accurate hole geometry and smooth sidewalls are essential, such as in plumbing, electrical, and HVAC installations in construction projects. Specialized bits like the Würth Diamond tile dry core bit are specifically engineered to prevent damage to delicate materials like ceramic tiles while delivering perfectly clean holes .

Longevity and Cost-Effectiveness

Despite their higher initial cost, diamond core bits offer exceptional long-term value through extended service life and reduced replacement frequency. The impregnated diamond core bits manufactured by companies like Hunan Diyfia are designed to continuously expose fresh diamonds as the matrix wears, maintaining cutting efficiency throughout the bit’s lifespan 6. This durability makes them particularly cost-effective for large-scale drilling operations where frequent bit changes would significantly impact productivity.

Versatility Across Materials

Diamond core bits demonstrate remarkable versatility, capable of drilling through an extensive range of materials including:

- Concrete and reinforced concrete: Standard application in construction

- Natural stone and masonry: Including granite, marble, and limestone

- Ceramic and porcelain tiles: Specialized dry bits prevent cracking

- Asphalt and composite materials: With specific bit designs

- Geological formations: For core sampling in exploration

Reduced Operator Fatigue

The efficient cutting action of diamond core bits requires less downward pressure and generates less vibration compared to conventional drilling methods. This reduction in physical strain translates to decreased operator fatigue, particularly important during extended drilling operations or when working overhead. The improved ergonomics contribute to both higher productivity and enhanced job site safety.

Applications and Uses of Diamond Core Bits

Diamond core bits serve critical functions across diverse industries, each with specific requirements that leverage the unique capabilities of these advanced tools.

Construction and Building Industry

In the construction sector, diamond core bits are indispensable for creating precise openings for utilities, HVAC systems, plumbing, and electrical conduits. Their ability to cut through reinforced concrete without damaging the structural integrity of the surrounding material makes them particularly valuable for renovation and retrofit projects. The 25-102mm laser-welded wet diamond core bits exemplify the specialized tools developed for these applications, offering high-speed drilling with clean results in concrete and reinforced concrete .

Oil and Gas Industry

The petroleum sector relies heavily on advanced diamond core bit technology for exploration and production drilling. PDC bits have become increasingly prevalent in oilfield applications due to their superior durability and drilling efficiency compared to traditional roller cone bits. Recent innovations like the StrataBlade concave diamond element bits have demonstrated significant improvements in drilling performance, with field tests across major shale basins showing consistent ROP improvements .

Specialty Applications

Beyond these major industries, diamond core bits serve numerous specialized functions:

- Semiconductor manufacturing: The development of 100mm single-crystal diamond wafers represents a breakthrough that could revolutionize thermal management in high-power electronics 9. While not a drilling application per se, this innovation demonstrates the expanding potential of diamond technology.

- Tile and masonry work: Specialized diamond core bits like the Würth M14 series enable professionals to create perfect holes in delicate ceramic materials without water cooling, preventing damage to finished surfaces .

- Infrastructure development: Large-diameter diamond core bits are essential for creating openings for utilities, drainage systems, and access points in major infrastructure projects.

Selection Guidelines and Usage Tips

Choosing the appropriate diamond core bit for a specific application requires careful consideration of multiple factors to ensure optimal performance and cost-effectiveness.

Material Compatibility Assessment

The first step in selecting a diamond core bit involves identifying the primary material to be drilled. Different materials require specific bit designs and diamond configurations:

- Soft concrete and brick: Standard surface-set bits with more aggressive diamond exposure

- Reinforced concrete: Hard-bonded bits with heat resistance for steel reinforcement

- Abrasive sandstone: Impregnated bits with durable matrix formulation

- Ceramic and porcelain: Fine-grit diamond particles with specialized segment design

Equipment Compatibility Check

Ensuring compatibility between the diamond core bit and the drilling equipment is essential for both safety and performance. Key considerations include:

- Thread type compatibility: Standard connections include 1/2″ BSP, M14, M16, and 5/8″-11 thread 18

- Equipment power requirements: Ensuring adequate torque and RPM capabilities

- Cooling system compatibility: Matching wet/dry bits with appropriate equipment

Operational Best Practices

Proper operation significantly extends bit life and ensures optimal performance:

- Adequate cooling: Maintaining proper water flow for wet bits or appropriate drilling intervals for dry bits

- Optimal pressure: Applying sufficient pressure for efficient cutting without excessive force that causes overheating

- Regular cleaning: Clearing debris from holes and bit segments to prevent clogging

- Speed adjustment: Modifying RPM based on material hardness and bit diameter

Maintenance and Storage

Proper maintenance extends diamond core bit life and maintains cutting performance:

- Thorough cleaning after each use to remove debris from segments

- Proper storage in protective cases to prevent diamond damage

- Regular inspection for segment wear or damage before each use

- Sharpening procedures for impregnated bits when cutting performance decreases

Innovations and Future Trends in Diamond Core Bit Technology

The diamond core bit industry continues to evolve, with ongoing research and development focused on enhancing performance, expanding applications, and reducing costs.

Advanced Materials and Manufacturing

Recent advancements in material science have led to significant improvements in diamond core bit technology. The development of premium-grade synthetic diamonds with carefully controlled properties has enabled manufacturers to optimize diamond concentration and distribution for specific applications . Additionally, innovations in metallurgy and diamond/metal bonding techniques have resulted in more durable matrix materials that extend bit life in challenging formations .

Specialized Geometry and Hydraulics

Bit manufacturers are increasingly focusing on optimized hydraulic designs that improve cooling and debris removal, enhancing both drilling efficiency and bit life. The StrataBlade concave diamond element bits with their unique geometry represent this trend, featuring a distinctive concave design that decreases the effective cutter back-rake angle for deeper penetration 10. Similarly, the CorePlus Diamond Dry Core Drill Bit incorporates a ribbed core body and V-groove segments that enable fast clearing of debris, allowing for continuous fast cutting action .

Integration with Digital Technologies

The future of diamond core bit technology includes greater integration with digital systems for precision monitoring and control. Smart drilling systems that adjust parameters in real-time based on formation feedback are becoming more prevalent, particularly in oil and gas applications. These systems optimize bit performance and prevent damage by adapting to changing formation characteristics during drilling operations.

Environmental and Efficiency Considerations

Growing emphasis on sustainability is driving innovation in energy-efficient drilling technologies. Diamond core bits contribute to these goals through reduced drilling time and lower energy consumption compared to conventional methods. Additionally, the development of dry drilling systems that eliminate water usage addresses environmental concerns in water-sensitive areas while maintaining drilling efficiency .

Conclusion: The Future of Drilling with Diamond Core Bits

Diamond core bits have established themselves as indispensable tools across numerous industries, offering unmatched performance in drilling through challenging materials. From construction and mining to specialized applications in semiconductor manufacturing, these advanced cutting tools continue to evolve through continuous innovation in materials, design, and manufacturing processes.

The future of diamond core bit technology promises even greater efficiency, precision, and versatility as manufacturers incorporate insights from materials science, digital technologies, and advanced engineering. The ongoing development of specialized bits for specific applications, coupled with improvements in diamond quality and matrix formulations, will further expand the capabilities of these remarkable tools.

As global infrastructure development continues and exploration for resources moves into more challenging environments, the importance of diamond core bit technology will only increase. Professionals across industries can expect to see continued advancements that enhance drilling efficiency, reduce operational costs, and enable new applications that are currently beyond our technical capabilities.

Whether creating precise openings in reinforced concrete, obtaining core samples from deep beneath the Earth’s surface, or enabling breakthroughs in electronic thermal management, diamond core bits will continue to play a vital role in shaping our built environment and expanding our understanding of the natural world.

Post time: Aug-31-2025