The Ultimate Guide to Wood Auger Drill Bits: Precision, Power, and Performance in Professional Woodworking

Wood auger drill bits represent the pinnacle of specialized drilling technology for woodworking. Unlike standard twist bits or spade bits, augers feature a unique spiral design that channels debris upward while creating exceptionally clean, deep holes with minimal effort. From furniture makers to door installers, professionals rely on these bits for tasks demanding precision in depth, diameter, and finish—whether crafting dowel joints, running wiring through beams, or installing cylindrical locks.

Core Engineering & Features

1. Advanced Flute Design & Cutting Geometry

- Multi-Flute Configuration: Premium auger bits feature 3-4 helical flutes (grooves) that act like conveyor systems, efficiently ejecting wood chips upward. This prevents clogging in deep holes (up to 300–400 mm) and reduces heat buildup. Single-flute designs suit softer woods, while 4-flute variants excel in hardwoods or resinous timber .

- Screw Tip Pilot: A self-feeding screw point at the tip pulls the bit into the wood, eliminating wandering and ensuring hole accuracy from the first revolution. This contrasts with spade bits, which require firm pressure and often drift off-mark .

- Spur Cutters: Sharpened edges on the bit’s periphery slice wood fibers cleanly before the main body lifts material, resulting in splinter-free entry and exit holes—critical for visible joinery.

2. Shank Engineering for Power & Compatibility

- Hex Shank Dominance: Over 80% of modern augers use 6.35mm (1/4″) or 9.5mm (3/8″) hex shanks. These lock securely into quick-change chucks (e.g., impact drivers) and prevent slippage under high torque. SDS and round shanks remain niche options for specialized rigs .

- Reinforced Collar: High-stress models include a thick steel collar below the shank, preventing flex during aggressive drilling in dense oak or maple.

3. Material Science: From HSS to Carbide

- High-Speed Steel (HSS): The industry standard for balance of cost and durability. Retains sharpness up to 350°C and withstands 2–3x resharpening cycles. Ideal for general carpentry .

- High-Carbon Steel: Harder than HSS but more brittle. Best for high-volume softwood drilling where edge retention outweighs impact resistance .

- Carbide-Tipped: Features brazed tungsten carbide cutting edges for drilling abrasive composites, laminated wood, or frozen timber. Lasts 5–8x longer than HSS but at a 3x price premium .

Table: Auger Bit Material Comparison

| Material Type | Best For | Drilling Life | Cost Factor |

|---|---|---|---|

| High-Carbon Steel | Softwoods, high-volume work | Medium | $ |

| High-Speed Steel (HSS) | Hardwoods, mixed materials | High | $$ |

| Carbide-Tipped | Composites, abrasive woods | Very High | $$$$ |

Technical Advantages Over Conventional Bits

- Depth Capability: Augers drill up to 10x their diameter deep (e.g., 40mm bit → 400mm depth) without binding—unmatched by Forstner or spade bits .

- Speed & Efficiency: The screw tip pulls the bit at 2–3x the feed rate of a twist drill, cutting 25mm-deep holes in hardwoods in under 5 seconds with a 1,000 RPM drill .

- Precision Tolerances: Industrial-grade bits (e.g., ISO9001-certified) hold diameters within ±0.1mm, critical for dowel pins or lock installations. Inconsistent bits (e.g., 1″ bit with 7/8″ twist) fail in guided jigs, while true 1:1 ratio bits succeed .

- Chip Clearance: Flutes evacuate 95%+ of debris, reducing friction and preventing “cooked wood” scorching in holes deeper than 150mm.

Technical Specifications & Selection Guide

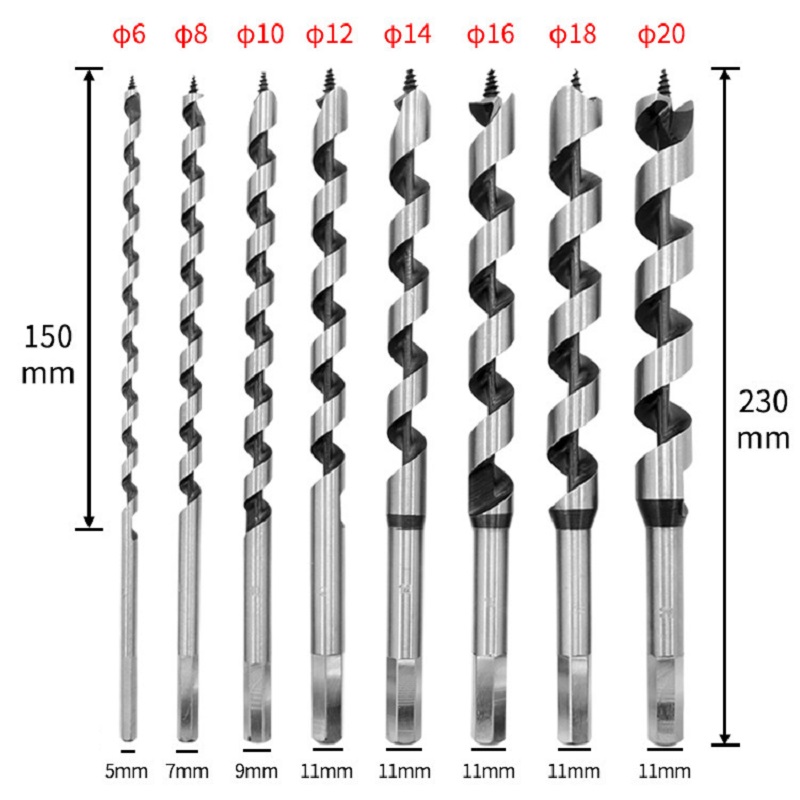

Sizing Standards

- Diameter Range: 5mm–100mm (task-specific):

- 6–10mm: Doweling, electrical conduits

- 15–40mm: Lock cylinders, plumbing pipes

- 50–100mm: Structural beams, large-diameter joinery

- Length Classes:

- Short (90–160mm): Cabinetry, door latch holes

- Long (300–400mm): Timber framing, deep mortises

Coatings & Surface Treatments

- Black Oxide: Reduces friction by 20% and adds mild corrosion resistance. Standard for HSS bits.

- Bright Polished: Smooth surface minimizes resin adhesion in pine or cedar. Common in food-safe applications .

- Titanium Nitride (TiN): Gold-colored coating for 4x wear resistance; rare in augers due to cost.

Table: Shank Types & Compatibility

| Shank Type | Tool Compatibility | Torque Handling | Use Case |

|---|---|---|---|

| Hex (6.35mm/9.5mm) | Impact drivers, quick-chuck drills | High | General construction |

| Round | Traditional braces, hand drills | Medium | Fine woodworking |

| SDS-Plus | Rotary hammers | Very High | Drilling into wood with embedded nails |

Real-World Applications & Pro Tips

- Door Lock Installation: Use 1″ diameter augers (with true 1″ twist) for latch holes. Avoid spade bits—they tear out mortise edges and deviate in deep cuts .

- Timber Construction: Pair 12″–16″ long 32mm augers with high-torque drills (≥650 Nm) for railing posts or beam joinery. Add paraffin wax to flutes when drilling resinous wood.

- Furniture Making: For dowel joints, select bits 0.1mm wider than dowels to allow adhesive expansion.

Quality Assurance & Certifications

Top manufacturers adhere to ISO 9001 standards, validating hardness (HRC 62–65 for HSS), dimensional accuracy, and load testing. Bits undergo sample destruction tests to ensure torsional strength exceeds 50 Nm .

Conclusion: The Indispensable Woodworking Workhorse

Wood auger drill bits merge centuries-old mechanical principles with modern metallurgy. Their optimized chip evacuation, depth capacity, and precision make them irreplaceable for professionals who value speed without sacrificing quality. When selecting a bit, prioritize certified HSS or carbide-tipped models with hex shanks and multi-flute designs—investments that repay themselves in flawless results and reduced workshop downtime.

Post time: Jul-26-2025