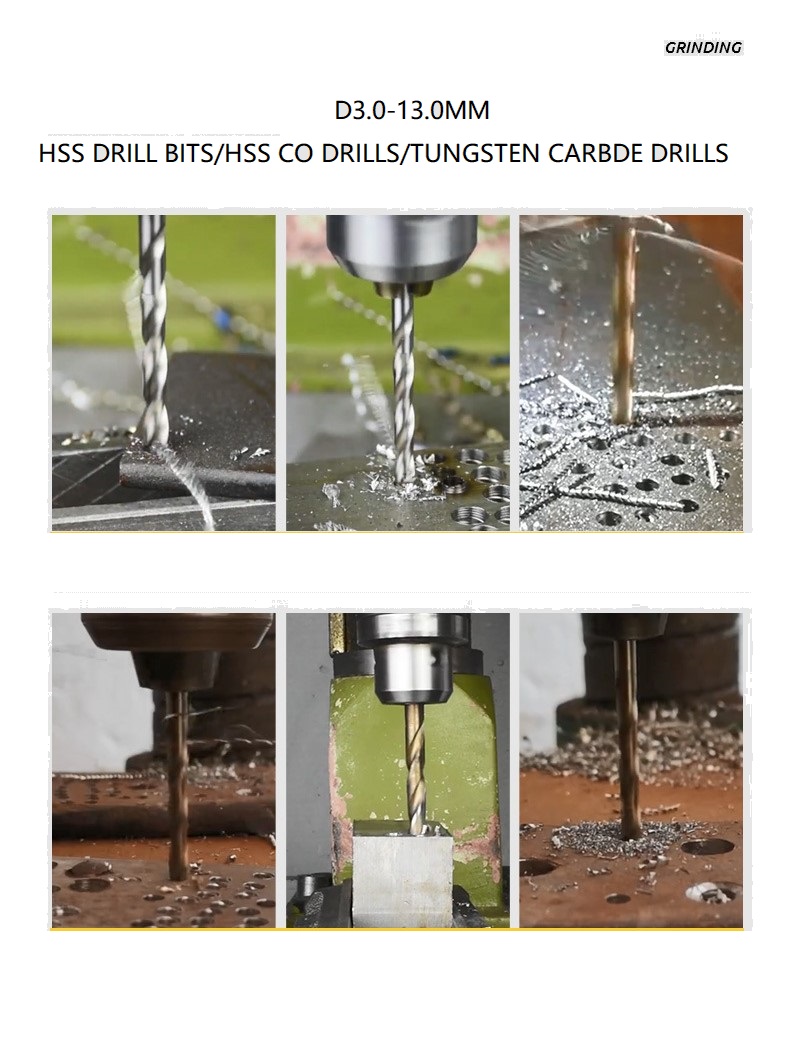

Precision Drill Sharpener for HSS Drill Bits,Tungsten carbide drill bits

Technical Specifications

| Model | ED-DS200 |

|---|---|

| Power | 150W Electric |

| Voltage | 110V/220V (Auto-Sensing) |

| Grinding Wheel | Diamond-coated (replaceable) |

| Sharpening Range | 3mm – 20mm (1/8" – 13/16") |

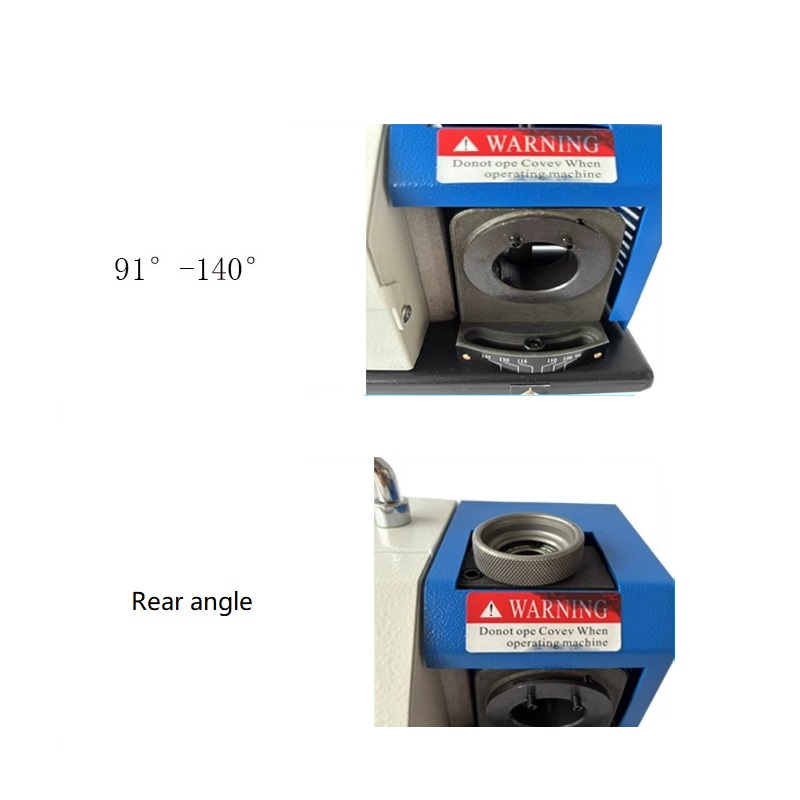

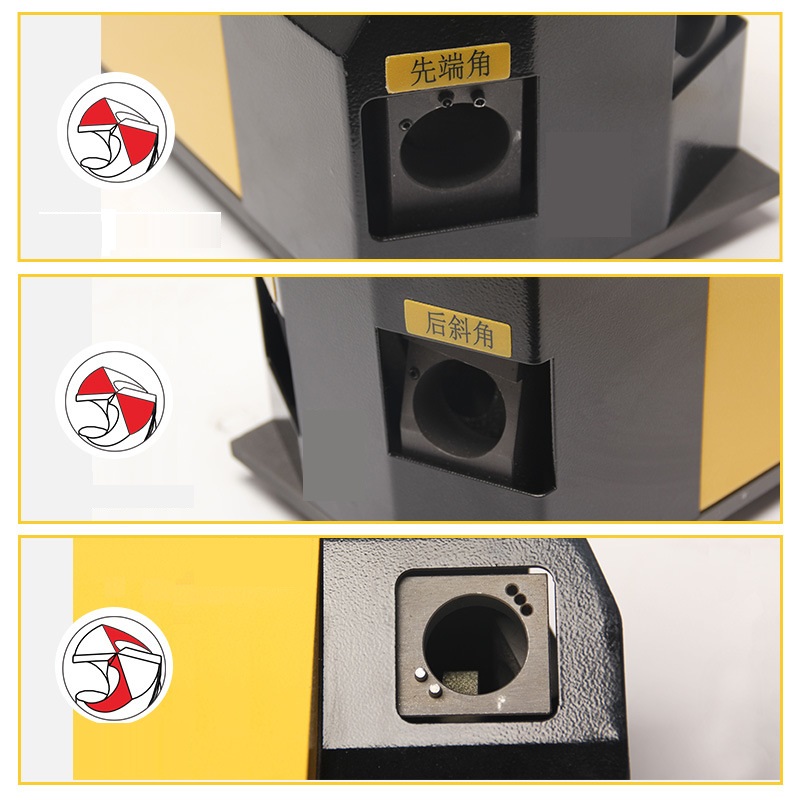

| Point Angles | 118° & 135° |

| Speed | 5,000 RPM |

| Dimensions | 3700 x 210 x 205mm |

| Weight | 9 kgs |

| Warranty | 1 Years |

PRODUCT show

Advantages

1. Extends Drill Bit Lifespan

Dull drill bits wear out faster and often end up discarded prematurely. A drill sharpener restores worn-out edges, effectively extending the tool’s lifespan by up to 5–10 times. This reduces the frequency of replacements and maximizes your investment in high-quality bits.

2. Significant Cost Savings

Constantly buying new drill bits adds up quickly. By sharpening existing bits, you slash operational costs and minimize downtime. For businesses using hundreds of bits annually, this translates to substantial savings.

3. Enhances Drilling Precision

Sharp bits deliver cleaner, more accurate holes with minimal burring or material damage. A drill sharpener ensures consistent angles (e.g., 118° or 135° points), which is crucial for tasks requiring tight tolerances, such as aerospace or automotive manufacturing.

4. Boosts Productivity

Dull bits require excessive pressure and time to complete tasks. Sharpened bits drill faster and smoother, reducing project completion times and improving workflow efficiency.

5. Improves Workplace Safety

Blunt drill bits are prone to slipping, overheating, or breaking, posing safety risks. Sharpening eliminates these hazards by ensuring stable, controlled drilling and reducing the physical strain on operators.

6. Environmentally Friendly

By reducing the need for new drill bits, sharpeners help minimize metal waste and contribute to sustainable practices—a growing priority for eco-conscious industries.

7. Versatility Across Bit Types

Modern drill sharpeners are designed to handle twist bits, masonry bits, carbide bits, and more. This versatility makes them ideal for workshops with diverse drilling needs.

8. Maintains Consistency in Performance

Manual sharpening often leads to uneven edges, compromising results. Professional sharpeners ensure uniform sharpening angles and edges, guaranteeing reliable performance across every job.

9. Reduces Downtime

On-site sharpening eliminates the wait time associated with outsourcing repairs. With a drill sharpener, operators can restore bits instantly, keeping projects on schedule.