Type A Solid Carbide Center Drill Bits

FEATURES

Material: Solid carbide center drill bits are made from solid carbide, which is a tough and wear-resistant material. This ensures durability and long tool life, making them suitable for high-performance drilling.

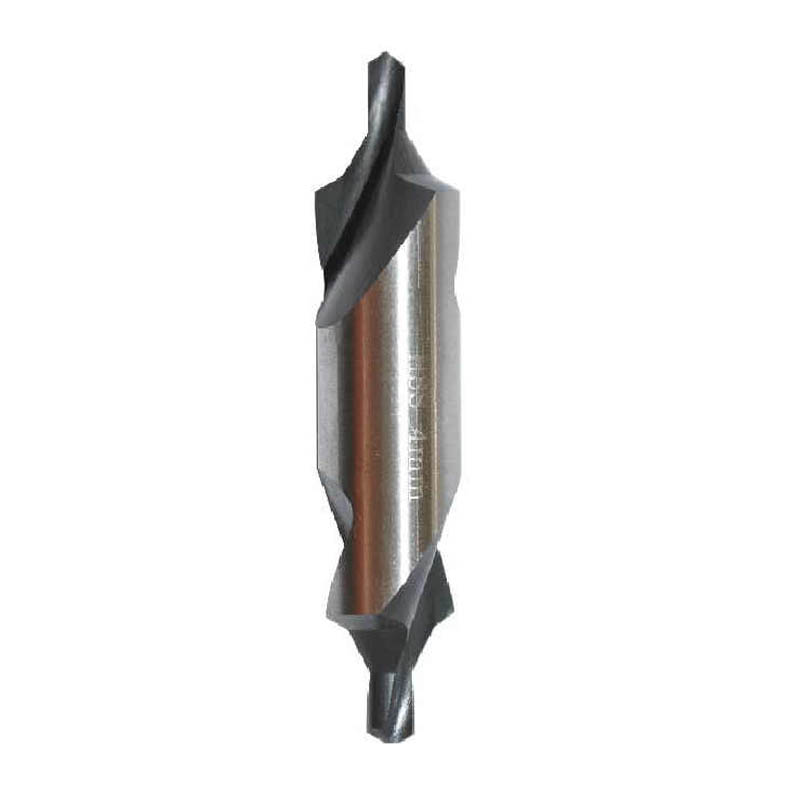

Design: Solid carbide center drill bits have a specific design with a conical tip and a double-ended configuration. The tip is often at a 60° angle, which allows for accurate centering and chamfering.

Shank: These drill bits typically have a straight shank that can be inserted into a drill chuck or collet for easy and secure attachment to the drilling machine.

Flutes: Solid carbide center drill bits often have two or four flutes, which help to evacuate chips from the hole during drilling. The flutes also provide stability and rigidity to the drill bit, reducing the chance of wandering or deflection during drilling.

Point Geometry: The conical tip of a solid carbide center drill bit features precise point geometry. This geometry ensures the creation of accurately centered holes and helps prevent the drill bit from drifting off-center.

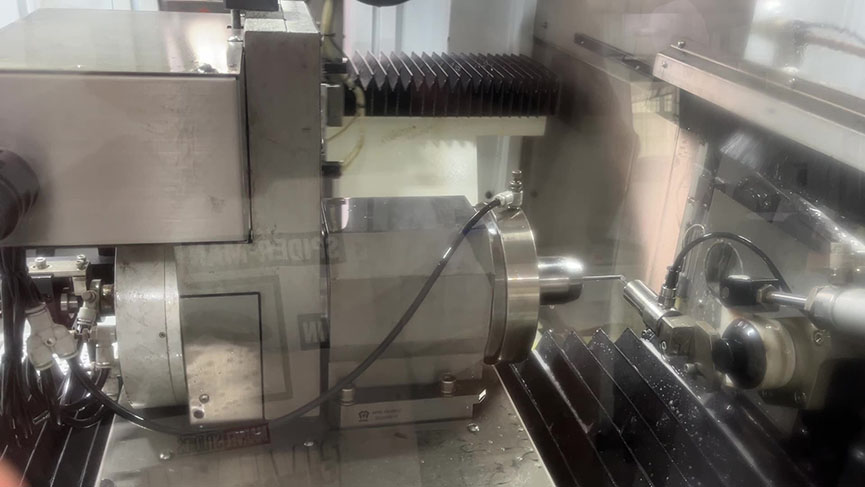

Hardness: Solid carbide center drill bits have high hardness, which allows them to withstand high drilling speeds and feed rates. This makes them suitable for use in CNC machines and other high-performance drilling applications.

Versatility: Solid carbide center drill bits are commonly used in metalworking applications, such as spot drilling, chamfering, and centering. They can be used with various metals, including steel, stainless steel, aluminum, and more.

Cutting Performance: Solid carbide center drill bits offer excellent cutting performance due to the high hardness of carbide material. They can cut through metal with minimal effort and provide clean, accurate holes with reduced burrs.

Longevity: Solid carbide center drill bits have a long tool life due to the wear-resistant nature of carbide material. This allows for prolonged use before needing to be replaced, resulting in cost savings over time.

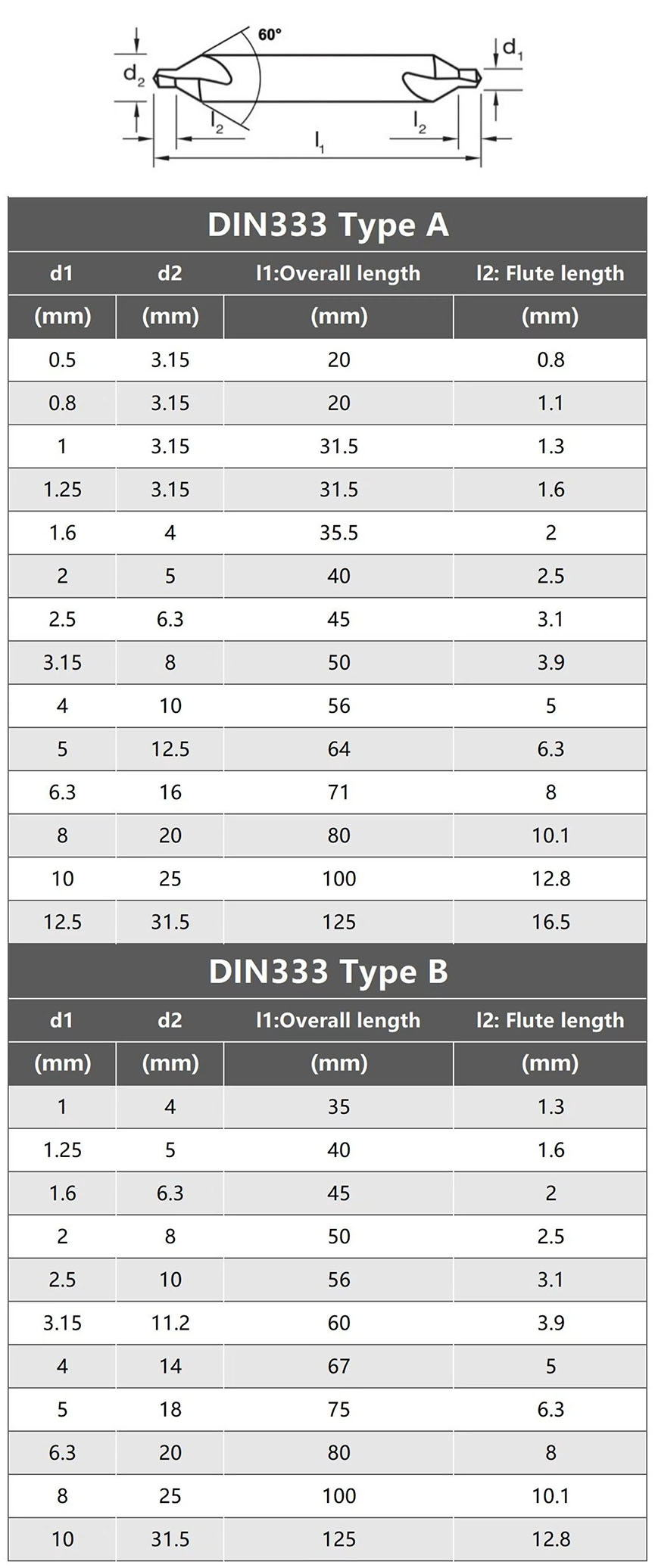

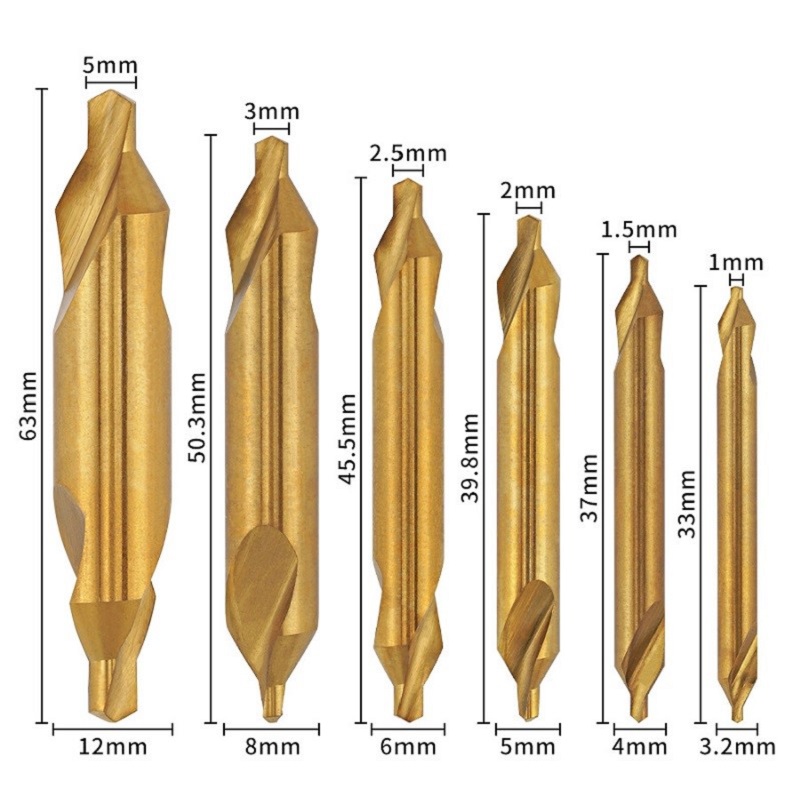

Size Range: Solid carbide center drill bits are available in various sizes, allowing for versatility and the ability to match specific hole diameter requirements.

center drill bits machine

Advantages

1. Hardness and Wear Resistance: Carbide center drill bits are made from a combination of carbide and cobalt, which makes them extremely hard and durable. This hardness enables them to withstand the abrasiveness of various materials, resulting in less wear and longer tool life.

2. Precision Drilling: Carbide center drill bits are known for their ability to create precise starter holes. The sharpness and rigid construction of these drill bits allow for accurate centering and positioning, reducing the chances of drilling off-center or causing damage to the workpiece.

3. Chip Evacuation: Carbide center drill bits are designed with specially designed flutes or channels. These flutes help in efficient chip evacuation during drilling, preventing the chips from clogging the hole and reducing the risk of workpiece damage or poor hole quality.

4. Versatility: Carbide center drill bits are suitable for drilling a wide range of materials, including metals, plastics, composites, and more. This versatility makes them a valuable tool in various industries, such as automotive, aerospace, engineering, and woodworking.

5. High Heat Resistance: Due to their carbide composition, these drill bits offer high thermal resistance. This allows them to withstand high drilling speeds and feed rates without compromising their performance or causing heat-induced damage to the workpiece.

6. Improved Productivity: The durability and precision of carbide center drill bits simplify the drilling process, resulting in improved productivity. Operators can rely on these drill bits to consistently deliver accurate and clean holes, minimizing the need for rework or additional drilling operations.

7. Reduced Vibration and Deflection: Carbide center drill bits have excellent rigidity, which reduces vibration and deflection during drilling. This ensures stable and controlled drilling, resulting in better hole quality and increased tool life.

8. Cost Savings: Although carbide center drill bits may have a higher upfront cost compared to other drill bits, their longevity and performance justify the investment. The extended tool life reduces the frequency of tool replacements, resulting in long-term cost savings.